Welcome to our Company

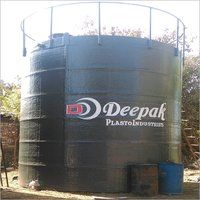

Vertical FRP Storage Tank

16 INR/Liter

Product Details:

- Application Industrial

- Condition NEW

- Capacity 1000-5000 L, 5000-10000 L Liter/day

- Product Type FRP Storage Tank

- Usage Industrial

- Color Grey

- Size Customized

- Click to View more

X

Vertical FRP Storage Tank Price And Quantity

- 16 INR/Liter

- 1 Piece

Vertical FRP Storage Tank Product Specifications

- FRP Storage Tank

- Industrial

- NEW

- 1000-5000 L, 5000-10000 L Liter/day

- SS316L, SS304, SS316, SS304L

- Industrial

- Grey

- Customized

Vertical FRP Storage Tank Trade Information

- 5 Piece Per Month

- 3 Week

- All India

Product Description

We are one of the leading manufacturers of Vertical FRP Storage Tank in the market. It is widely used in chemical, petroleum, transportation, textile, water irrigation, electronics and many other industries. Vertical FRP Storage Tank has gained us high rising applaud and demands from our customers among that of our competitors.

FAQs of Vertical FRP Storage Tank:

Q: How is the Vertical FRP Storage Tank suitable for industrial applications?

A: The Vertical FRP Storage Tank is designed with industrial-grade materials such as SS316L, SS304, SS316, and SS304L, making it ideal for handling corrosive and non-corrosive substances commonly used in industrial applications.Q: What capacities are available for the Vertical FRP Storage Tank?

A: The Vertical FRP Storage Tank is available in capacities ranging from 1000-5000 liters and 5000-10000 liters per day, catering to various industrial requirements.Q: When is a customized size recommended for this storage tank?

A: A customized size is recommended when unique space constraints or specific industrial storage needs require a tank design beyond standard dimensions.Q: Where can the Vertical FRP Storage Tank be used effectively?

A: It can be effectively used in various industrial sectors such as chemical manufacturing, water treatment plants, and food processing units that require durable and corrosion-resistant storage solutions.Q: What are the benefits of the Grey color for this storage tank?

A: The Grey color offers better resistance to UV exposure, reduces heat absorption, and provides a clean appearance, making it suitable for industrial environments.Q: How does the material grade impact the tanks performance?

A: The material grades SS316L, SS304, SS316, and SS304L enhance the tanks resistance to chemical corrosion, temperature fluctuations, and mechanical stress, ensuring long-term reliability and efficiency in industrial usage.Q: What is the process of installing a Vertical FRP Storage Tank?

A: Installation involves site assessment, foundation preparation, positioning of the tank, and assembly of inlet/outlet fittings, which should be carried out by skilled professionals to ensure proper functionality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email